The Evolution of Membrane Switch Technology in the Car Electronics

The Evolution of Membrane Switch Technology in the Car Electronics

Blog Article

Checking Out the Perks of Membrane Layer Switches for Modern Electronic Devices

The expedition of membrane layer buttons in contemporary digital tools uses a remarkable point of view on their myriad advantages, specifically in terms of style flexibility, durability, and cost-effectiveness. As markets continue to advance, the role of membrane layer switches in boosting customer experience and functional performance warrants more detailed evaluation.

Benefits of Membrane Buttons

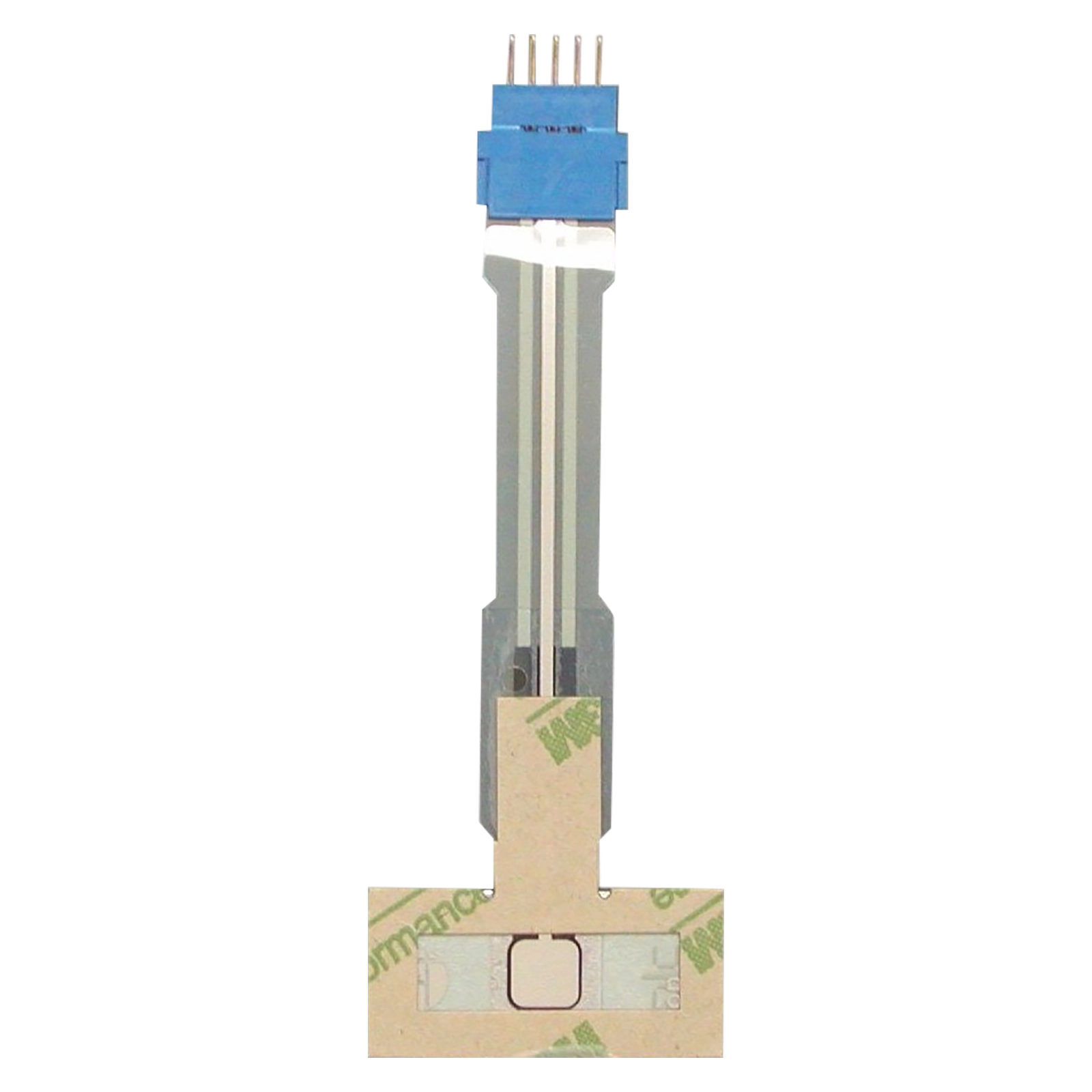

Membrane buttons are progressively favored in contemporary electronic devices because of their various benefits. Among the main benefits is their small style, which permits space-efficient assimilation right into different tools. This slim profile not just saves space but also adds to the general visual allure of digital items.

One more advantage is their longevity. Membrane buttons are usually immune to wetness, dirt, and impurities, making them suitable for use in atmospheres where direct exposure to extreme conditions is an issue. This resistance prolongs the lifespan of the switches, lowering the need for constant substitutes and upkeep.

In addition, membrane switches over offer exceptional responsive comments, enhancing individual experience. The responsive reaction is often made to provide a gratifying sensation upon activation, which can improve user satisfaction and efficiency.

Furthermore, the manufacturing process of membrane buttons is cost-effective, enabling reduced production costs contrasted to standard mechanical buttons. This affordability makes them appropriate for a large range of applications, from customer electronic devices to commercial machinery.

Design Adaptability and Personalization

The layout flexibility and customization options provided by membrane layer switches over even more enhance their appeal in contemporary electronics. These switches can be customized to meet specific aesthetic and useful needs, allowing manufacturers to create devices that line up carefully with brand name identification and individual choices. With numerous choices in regards to colors, shapes, and dimensions, membrane buttons can effortlessly integrate into diverse product layouts, whether for consumer electronics, industrial applications, or clinical gadgets.

In addition, the capability to integrate graphics and icons directly onto the switch surface area boosts use while minimizing the demand for extra labeling. This integration not only simplifies manufacturing processes however likewise contributes to a sleeker general appearance. The design can be additional customized with functions such as backlighting, tactile comments, and multi-layer buildings, offering improved user communication.

Resilience and Environmental Resistance

Moreover, membrane buttons can be crafted to be chemically immune, making them appropriate for applications in commercial settings where exposure to solvents and cleaning agents prevails. The encapsulation of digital parts within the membrane layer structure gives additional security against environmental tensions, ensuring reliable efficiency also in difficult problems.

In enhancement to physical resilience, membrane layer changes exhibit outstanding resistance to UV light, avoiding degradation and discoloration gradually (membrane switch). This particular is especially advantageous for outdoor applications, where prolonged direct exposure to sunlight can jeopardize various other switch kinds

Eventually, the durability and ecological resistance of membrane switches make them an ideal selection for a vast array of contemporary electronic devices, from clinical equipment to consumer electronics, ensuring regular functionality and individual fulfillment across numerous applications.

Cost-Effectiveness in Manufacturing

Cost-effectiveness in production is a considerable benefit of membrane layer switches, making them a favored choice for manufacturers in numerous markets. The manufacturing procedure of membrane changes typically entails less materials contrasted to traditional switches, which lowers basic material expenses. This structured production process not just saves money however also minimizes waste, lining up with modern sustainability goals.

Furthermore, membrane layer switches Click This Link can be created making use of automated strategies, permitting for high-volume outcome with reduced labor prices. The assimilation of sophisticated printing innovations even more enhances effectiveness, allowing makers to achieve intricate designs and capabilities without incurring considerable added expenses. This scalability makes certain that production can adjust to transforming market needs without compromising high quality or boosting expenses.

Additionally, the lightweight nature of membrane changes contributes to set you back financial savings in shipping and handling, along with in the total design of electronic tools. By eliminating large components, suppliers can maximize the total product style, thereby enhancing market competitiveness. In general, the cost-effectiveness of membrane switches over not only benefits manufacturers financially yet additionally facilitates innovation and rapid item growth in the vibrant landscape of contemporary electronic devices.

Applications in Different Industries

Flexibility sticks out as a characteristic of membrane switches, enabling them to find applications across a vast variety of industries. In the healthcare industry, these buttons are indispensable to medical devices, providing easy to use interfaces for equipment like infusion his response pumps and analysis makers. Their resistance to moisture and very easy cleaning make them ideal for environments needing strict health criteria.

In the vehicle market, check out here membrane layer switches add to the performance of control panels and control panels, offering a smooth, contemporary look while guaranteeing toughness against extreme conditions. Their light-weight design also supports general lorry performance.

Additionally, commercial machinery employs membrane switches for operational controls. Their robust nature and adjustable attributes cater to the particular requirements of varied applications.

Verdict

In conclusion, membrane switches offer considerable advantages for modern-day electronics, including layout flexibility, resilience, and cost-effectiveness. membrane switch. Their personalized features and resistance to environmental variables make them appropriate for a large range of applications throughout different sectors. As technological needs remain to progress, the versatility and performance of membrane layer switches placement them as a vital component in improving individual experience and driving development within the affordable landscape of electronic tools

Report this page